Machines of European origin is good preferably having ISO standards. Check for their presence in India.

Cleaning chemicals are available in India - of both alkaline and acidic nature. Its available in India freely. Everyday evening use alkaline detergent in slightly warm water, add 20% detergent and top it up with 80% water, one in 3 days use acidic detergent in the same ratio which removes the milk stains in cluster and stainless steel or aluminium cans. Now a days most machines are with 30 liter ss cans. Better to use iodine based teat dips also for teat dipping. Use non return dip cup so that once dipped iodine solution cannot go back to the cup again and it has to be thrown out. Non return dips cups are available in India.

Murali Krishnan

srivinayakatvm@gmail.com

[quote=Nikhilthakkar]

Thank you for detailed explanation on machine. Please advice few good brands of machine as advised below and approx cost. Are cleaning chemicals available easily in India and please advice on this too.

Regards Nikhil

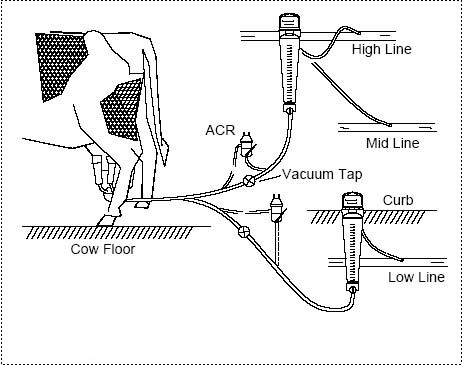

One can cluster can milk 10 cows in one hour(electrically driven machine takes 6-8 minutes to milk one cow irrespective of its yield). Buy machines giving careful thoughts, don’t buy some “scrap” called milking machine. Please think why machines working using hand pumps and leg operated ones are not seen in gulf countries or USA, Australia or New Zealand? The reason is they are technically not working in the right methods and applying recommended vacuum levels. A good machine must milk the cow pressing opposite teats- one on the left side in the front quarter and the right teat at the back quarter like how we mark “X”. Definitely they are having better machines for all other purposes. Then why only in milking?

A good milking machine will have the following:

• Electrically driven vacuum pump, oil free.

• Vacuum gauge

• Vacuum meter

• Aluminium or SS milking can of 30 litre capacity.

• Pneumatic pulsator, oil free

• Liners, Milk sight glass, Teat cup Shell transparent, Teat Cup Shell Stainless steel part, one set of 3 brushes.

Machines having European standards and ISO certifications are the best and not from countries from where we normally get throw away Tape Recorders or DVD players. The country of origin is very important.

There is no harm in using a milking machine. It can never take blood out of the cow even if you keep it there for 15 minutes after completing the milk let down. No harm is caused to the cow as the vacuum is passed on to the cow’s teats after regulating it. You will get good clean milk without froth from the machine. The only thing is after milking you need to open the milking can lid, measure the milk and pour it to another preferably SS or Aluminum vessel. Avoid milk getting touched by hands as it prevents mutiplication of microbial content in milk and can last for more time. It’s always better to chill it immediately after milking. For that too never depend on locally made coolers. Go for Company made coolers only.

Locally made stuff will give you trouble and draw more electricity.

If you have 2 milking can machine, for 25 cows I think in 1.5 hours your job will be done. Ladies can operate this machine. Just attach and detach milking clusters to the cow’s udder. Its always better to use iodine after milking to dip the cows teats. Iodine is a disinfectant and it helps the cow to close the opened teat canal. I think I have given a very detailed reply clearing your doubt. Happy Milking !!

When there is no milk seen in the milk sight glass (In machines imported from Turkey, you have two piece liners, with a milk sight glass in between having a transparent part between the liner and the short milk tube). In other machines, single piece liner or in the milk claw bowl bottom (the transparent part in which you can see milk getting collected from each teat), you please put the weight of your right hand in the milk claw so that extra weight is added to the milk claw bowl bottom part. Remember to put your hand on the dark part, over the top of the milk claw bowl bottom( the piece where the rubber liners are attached to the plastic part,normally its above the transparent part), so that it gives that extra weight on the four teats of the cow, like you squeeze the last milk from the teats . When the milking is about to be over, the same action is done by putting little extra weight. The milk sight glass helps you to see the milk flowing out from the 4 teats as you don’t have to bend too much to see the bottom milk flowing from the 4 teats.

Milking is done using machines only in USA, NEW ZEALAND and AUSTRALIA. They are doing complete milking and they are very strict on teat dipping as well as hygiene practices after milking like teat dipping, wiping the udder using teat dip wipes{throw away type, you never use a used wipe}, washing utensils with acid and alkaline detergents. No soap or washing detergents. Complete milking is possible and their cows yield three times more than our cows. No fears please!!

Muralikrishnan