hai friends myself benak from tumkuru karnataka state, friends just now i completed my b.e in computer science at agreegate of 87%.But freined i m interested in dairy farm ,i have a agriculturre land of 5acre which as 2well,the well will filled with water througth out the year since the gubbi lake which is filled by hemavathi river. Sir please guid me to get well in this field,im planning to buy 10cows,so shall i buy HF cows. My plan is to do commercial dairy farm at the starting and after getting settle with this field ill also start desi baffalo farm also . But at the starting ill will be starting the commercial dairy farm. So please tell me which breed is best.what is the capacity of milking of that breed and what is the cost of the food for one cow.

Hello,

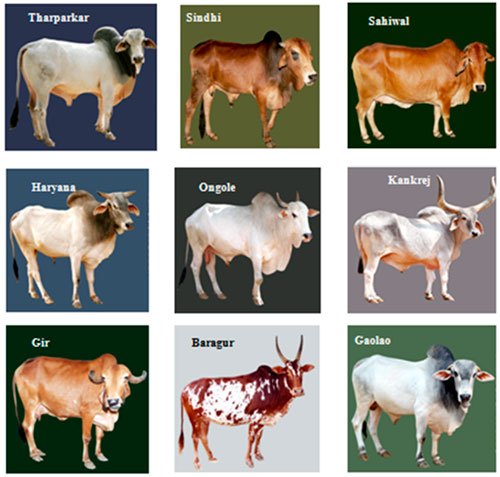

You may go for a mix of Indian breeds, Holstein Fresian, Jersey. Buy just two Indian breed cows and one Holstein cow first. Learn how to care of them. Understand their water and feed requirements. Buffalo handling is not easy as you think. Milk will be more in Holstein and less in other breeds. But fat percentage will be more on Indian cow milk. Learn how to cultivate fodder crops for cows. Understand the water needs of cows. Milk contains 90-95% water only. More water you give, more milk you get. Please note that cows can produce more milk, only if you feed them with properly with cattle feeds or locally available groundnut cake, gingelly cake, coconut cake, maize bran, wheat bran, rice bran, tapioca in dried form, greens, calcium and vitamin supplementation and hay at the end of the day, which helps in regurgitation. Production breed wise will vary but a good Holstein cow can give 15-22 litres in the morning, provided energy requirements of that cow is met & sufficient water given. Learn the importance of De-worming, it is very important. When to inseminate cows, signs of cows in heat has to be understood well. Good luck.

Murali Krishnan

Small Dairy Herd farming vs Large Dairy Herd (LDH) farming.

Big difference is there between the two. Total style of management will change plus the methods & systems there.

Large Dairy Herd (LDH).

The farming methods, feeding, milking, housing, cow care etc will change completely when it comes to big Farms normally seen in Middle East, USA, Turkey, and Australia etc. Here in most places the cow takes care of herself. The cows are free to move in their shed for rest, water and feed requirements.

Housing:

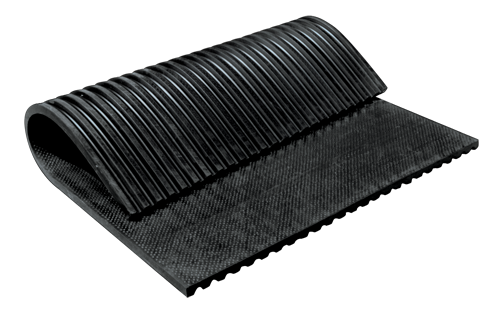

The cows say around 300 to 500 numbers are housed in a shed. The farm will be having sections or different sheds grouping various types of cows like freshly calved cows, those in mid lactation, end lactation, dry cows, just conceived cows, middle stage of pregnancy, cows about to calve, sick animals like that. The idea of keeping them in different sheds or sections helps the management give more care and attention like feeding rations, medicines, vaccinations, de-wormers, calcium and vitamin requirements etc. The cows will have separate resting areas, where another cow cannot disturb. They are separated using cow cubicles made of hot dip galvanized piping. On the floor, some farms use cow mats also to protect the cow from cold weather and from rough surface to protect them from injury caused in the udder, thigh and knee areas.

Feeding:

The cows can be given different feed schedule as per the cow’s energy requirement at that particular time. For e.g. freshly calved cows will be given feeds, greens and other supplements to boost production. Similarly, ration will be different for those in mid lactation, end lactation, dry cows & pregnant cows. Batch wise feeding ensures that the right cow gets the required energy levels needed for that cow to perform.

Breeding:

Natural breeding is one way out. Just leave a bull out with one set of cows, and the bull finds and mates with the cows on heat. One bull could be sufficient for a group of 30-50 cows. This will also depend on the age of the bull. Mature bulls can handle more cows; say 30-50 per season. Once in a while test the bull semen too. Quarantine your bull before you introduce him to your herd. You may keep him for 45-60 days on an average. Watch your herd well so as to get an idea. Heifers are calves that have not been bred before or have never calved earlier. It is recommended to wait for 15 months of age before breeding heifers for the first time. A ideal heifer should have at least 60 to 65% body weight of the herd before she is bred for the first time. Notice the estrus periods of the cow so that you can artificially inseminate her. A heifer can be successfully bred during her heat days.

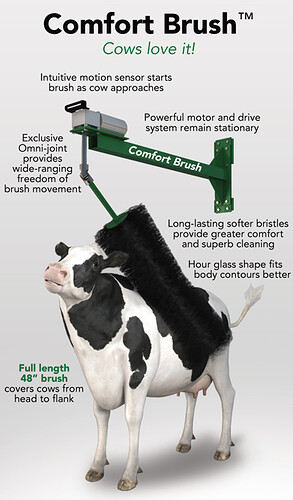

Cow brush: 2 brush system – one horizontal, one vertical -

With one horizontal and one vertical brush - a selective cleaning of the back, massage, stimulate and scratch the back of your cows, breast & sides. It supports the well-being of your cow herd.

Manure Scraper:

Manure Scraper is characterized by simplicity and flexibility. Easy to install, operate and maintain. The ideal solution for varying types of animal sheds. Hydraulic dung removal systems have an unsurpassed stability of value and long life span. Even in the field of cable-drawn dung removal sliders for free pens, it ensures a clean future. The shallow slurry drain in the deep slurry gutter reduces the methane emissions from the cowshed, contributing sustainably to protecting the environment and preserving the social acceptance of cattle farming.

See pictures below.

Murali Krishnan

srivinayakatvm@gmail.com

9447088234

Loose housing - Large Dairy Herd

Some of the main areas:-

cow cubicles - watch the first picture to see cubicles to make cow housing comfortable.

Milking Parlours

Manure scrapers

TMR Wagon

Watch the split roofing in the last picture

Murali Krishnan

Milking, udder care and teat dipping.

Complete and proper milking procedure is very important. Milking wet udders will increase the chance of mastitis problems. Teats, and not the udder, must be washed. Teat has to be clean and dry before the milking cluster unit is attached. Teats must be dipped after milking.

It’s important to provide a clean, stress-free environment for cows. A clean surrounding is essential to prevent environment induced mastitis. For maximum production, cows should have the minimum stress. Stress reduces the milk let down process. Handle cows calmly. Check foremilk and udder for mastitis. Examine the udder for swelling, heat or pain, and, using a strip cup or plate, examine the foremilk from each quarter prior to every milking. Wash the teats with an udder wash sanitizing solution. Washing each teat aids milk letdown and removes mud, dirt, manure and other foreign objects on the skin. Dry teats completely with an individual paper towel. Milking machines are designed to stay securely attached to a dry teat. Drying the teat also prevent possible contamination of the milk and teat by bacteria in the water running off the cow’s udder and teats. This water, if present, acts as a freeway for bacteria to enter the milking letting down system. Remember, the target of every mastitis-control program is to prevent the introduction of bacteria into a normal and healthy mammary gland. Attach the milking unit within one minute after the start of stimulation. The milk letdown process that follows the release of oxytocin, after udder stimulation is the highest for three to five minutes.

Adjusting units is necessary for proper alignment. Machine position and support should be adjusted as necessary during milking. Improper attachment of liners and liner slip have been associated with cross-quarter contamination. Shut off vacuum before removing unit. Stop the teat-end vacuum before removing the claw. This will help minimize cross-quarter contamination and adverse actions on the teat end. Teat-end lesions allow the invasion of bacteria from the environment into the mammary gland. Dip teats with an effective product immediately after unit removal. Post-milking teat dipping is regarded as the single most effective mastitis control practice in lactating dairy cows.

Dipping or spraying the teats immediately after milking has been practiced for many years. The aim of post-milking dipping is to remove any contagious mastitis-causing pathogens that may have been deposited on the teat surface - including any present just inside the opened teat canal - that are transferred during milking from infected milk residues from inside the liner and claw piece, before they have chance to colonize and infect the teat. Dip chemicals also kill bacteria present on any sores on the teats, promoting quicker healing.

Iodine-based treatments (iodophores), Chlorohexidine-based treatments, Hypochlorite-based treatments, Ammonium Compounds, Barrier dips, can be used to prevent infections on udder.

Murali Krishnan

Mera nam mahipal bishnoi h.

Me phalodi jodhpur Rajasthan ka rahne wala hi.

Me dairy farm start krna chahta hu.

10 cow se me dairy start krna chahta hu.

Holesteiñ freezen cow purchase krna chahta hu.

Mujhe pura kaam suru krne me help chahiye.

Bank loan

Shed

Other equipment etc

Dear Mr. Maheepal Bishnoi,

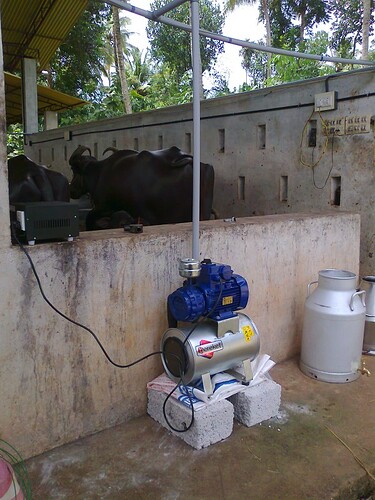

Please prepare a project report for the same through some veterinarian in your area. For 10 cow farm, the setting up might cost you around 10 lakh, including cow shed, cows, single can milking machine fixed type, cow mats, calf bottle for feeding calves etc. 1.25 acres of land needed for fodder cultivation. All waste water, urine, shed cleaning water should flow to the fodder growing area. Plant CO3 / CO4, Fodder maize also there. Plan for other money earning devices like Vermi composte using earthworms, production of organic manure which will move well in agriculture related area, Ghee, Butter, Curd, Buttermilk are some of the products which will earn you good money. Panchagavya is another product. Search for more information on the above subjects and plan one by one and not all together. Initially keep cows only. Keep accounts for milk received, milk sold, fodder making expenses, hay bought etc. Hay to be fed during evening time only as it motivates the cow for regurgitation, better for digestion and absorption. Use milking machine with single can assembly for milking, better use oil free machines. Go for low cost housing for cows. Ensure that good drinking water is there where you plan your cow shed.

GoodLuck!!

Murali Krishnan

Hi,

Is there any farm/institute in/near Mumbai where I can get a short term training in Dairy Farming?

Thanks,

Shatru.

Hi,

Thank you so much for sharing your knowledge and experience. Its wonderful. Thanks…!!!

1.Just want to know are there any dairy farming training courses available in Andhra Pradesh or Hyderabad?

2.Now a days, there is drought situation in Prakasam dist, hearing stories about farmers are selling cows/ buffaloes as they unable to feed them because of of severe water shortage. other issue is severe labor shortage.

Any one having / faced this issue ? how we can avoid these pain points ?

- There are many people dreaming to start career in dairy farming. Are NABARD and govt actions( loans and Subsidies) sufficient to dairy farmers? what are bottle necks avoid to succeed in this sector?

Appreciate your guidance and comments.

Thanks.

SS

Thank you Bhayya for your Generous IDEA to save the Milk feeding Animals !

Yes particularly in Drought Prone ares of Telanagana, Cuddapah,Prakasham, Ananthapur Districts,

the Farmers are selling the Animals to the Butcher Houses. Because of our GREEDY NATURE in

destroyed the Natural Forests, we are facing this worst situations.

We have evolved a system in Growing Fodder under Hydroponic way in small extent of land with less water.

(Not a System of Growing in Trays under Mechanical System with heavy Expenditure on Machinery). Our

system is effortless with lesser Expenditure for Growing Natural Grass in Natural Climate.The Grass under

Tray system is a Costly affair of seed (Pulses,cereals etc.). It is under Trail. After its success we will bring

it to all our Forum Members Notice.

In addition to the Above Diary Farm can be maintained very easily on Growing Azolla in avoiding the

costly Feed.All the details will be Provided Shortly.

MANNE.SN,

for vasudha Green Farms,

vasudhagreenfarms@gmail.com,

9133498366.

Wishing Vasudha farms, all the best in inventing methods for cheaper fodder production.

Good luck.

Murali Krishnan

We can provide (Rent Only) Livestock Breeding Shed for Green House Farming ,Poultry (Boiler & Layer),Goat, Sericulture etc + AGRO FARM SHED with 55 HP POWER Near Dabaspet ,Bangalore, Karnataka + Call :974 3605 888.

We are Industrial consultancy firm in India , we provide A to Z Business Solutions. We provide Consultancy on various Sector-

- Dairy farming, cow farming, Poultery, Goatery, Dairy Plant Setup.

- Ice cream Plant Consultant

- Food Processing Plants

- Plastic Industry many more industry

Call us for more Information 8981529691,

We are Industrial consultancy firm in India , we provide A to Z Business Solutions. We provide Consultancy on various Sector-

- Dairy farming, cow farming, Poultery, Goatery, Dairy Plant Setup.

- Ice cream Plant Consultant

- Food Processing Plants

- Plastic Industry many more industry

Call us for more Information 8981529691

Still Iam waiting to know a succesfull winner in dairy. Can any one come up with their success sory only in dairy?

Hi All ,

I would like to visit few farms in karnataka as i am planning to start a dairy , if anyone of you mail me your contact details on guruprasadht.m@gmail.com , it will be of great help .

Thanks