I found this vedio, Please see how pipes are welded instead of bending. Contact info is at the end.

youtube.com/watch?v=CWDYvdxMhjk

Dear sri,

good posting. …lokobinnaruchi…

kasturiraju.

Hi all,

The hydroponic machine which one we commissioned is really stabilised, now. Following few photos are attached for all of you peoples references.

We have observed the following points in last 15 days production:

- clean seeds and soaking is a very simple but important activity.

- Maintaining hygienic all around machine and cleaning trays is very important.

- water softening will increase the better growth of the fodder.

- continuous power supply with voltage regulation is essential.

- two normal labourer is sufficient for 4 hours/day for entire activities of handling 500 kgs produce of green fodder.

Some how, our taluk as well as our district has got very less rains this time(even from last two years). Where,the rest of Karnataka is getting good rains. In this condition, Hydroponics green fodder is really started to supporting us well, till now.

Will be sharing further progresses.

thanks and regards,

kasturiraju.

Hi

What seed you are using? If maize, where have you procured from and what price?

I found that market maize has lots of impurities and broken grains and contributes to mold formation, have you faced any issues?

I am still stuck with procuring good quality seeds, please suggest.

Thanks

Nikhil

Dear Nikhil,

At present we are using locally available yellow and white maize seeds. You have to communicate to a genuine trader/farmer to provide the cleaned,sieved seeds (preferably manually separated seeds to avoid the loss of nuke). It will cost you around Rs. 17,500-00 to 18,000-00. (in season it will be less by around Rs.2/-)

Initially , we purchased Rs.14,500/ton seeds and the germination was not good and as you said there was lots of impurities and un-size seeds etc., If, seed is very dry soak it for 12 hours and then put in trays.

thanks and regards,

kasturiraju.

Thanks for reply. Appreciate you being so open about discussing this technology.

We are working to bring down the cost of the machine to make it more affordable to local farmers, lets see what happens.

Nikhil

Dear Nikhil,

do it. keep communicating about progress and successful of the same. It it happens, it is good na. Infact, farming is starving for such economically successful solutions. what is, we are gaining by doing such things in secret, after all it is for struggling community.

All the best.

thanks and regards,

kasturiraju.

Hello,

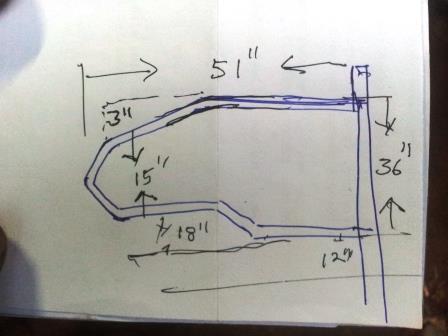

I got a Cow cubicle loop sample done at Mangalore. please find the picture attached. We have used 1.5 inch Tata B GI pipe. This needs some more modification as shown in the second picture (handwritten). Please share your inputs on the loop length and other dimensions in the handwritten picture.

Thanks,

-Ganapathi Bhat.

Hello,

Good job,

The top length and deep shall be maintained according to your requirement i.e space provided in your shed floor as well animal size.

You have not tried C class pipe? Any way how much it costed u finally?

Thanks n regards,

Kasturiraju.

one loop will cost around Rs. 1400 (900 for the GI pipe and 500 for the bending), transportation & installation is extra.

I am keeping 4 ft 3 inch as the length of the loop. is it sufficient ? should I increase the length ? I have medium size Jersey/HF cows.

Hi

Any reason to go for B class GI pipes? Other than anticorrosive features?

We have used MS pipes.

Pipe used - 1.5 inch 16 gauge MS pipe (Called coil tube in Mysore)

Weight of pipe for 20 feet length - 13 kg.

Cost of MS steel pipe - Rs. 56 per kg - For 13 kg - 728

We have used 1 pipe for 2 partitons, that is 10 feet per partition.

We have done C shape where length - 4 feet top and 4 feet bottom and height is 2 feet. Check attachments.

So cost for 1 partition is Rs. 728/2 = Rs. 364.

Bending charge is Rs. 100 per partition.

Anticorrosive coatings like Zinc Chromate followed by 2 coats of oil paint of your choice - Max. Rs. 20 per partition.

So total cost for 1 partition - 364 + 100 + 20 = Approx.Rs. 500. + Transport and installation extra as you have pointed out.

For 1 partition that you have done, you will get 3 partitions.

The partition is welded to vertical support, rarely cows will break the welded joint, you can weld it back.

As it does not come in contact with water or urine, corrosion is very less.

We have kept small welding set in our farm and do all alterations ourselves, its not that difficult.

Other regular maintenance is repainting with anticorrosive coating maybe once in 2 years depending on fading away of the coats.

I feel the cost savings in the partition intially justifies the extra small bit of work that needs to be done later on.

GI pipes are very useful in places where there is always water exposure, in this case its not required.

Think about it, personally I dont see any issues.

Good luck.

Nikhil

Hi all,

Thanks to share the details, this is how we all

Can share the details n save the cost as well as understand what are the possibilities to serve the purpose. This is how all dairy farmers has to discuss all type of issues without agitation to help/understand/support each other to move forward confidently.

Dear bhat: we think length mentioned is ok for adult animals for heifers you can size down accordingly. Also, u can share the contact no. Of workshop person to make use of. Surrounding other farmer’s to make use of his services.

Dear nikhil: realy simple good economical job done. Only. At the end of barricade u could have made the shape smoothen further.

Thanks n regards,

Kasturiraju.

I attended one day training on EM at Auroville organized by EcoPro. It was a very nice experience. Please find attached the notes. I am planning to use EM in my dairy farm. If you are interested to know about EM, I suggest you to attend the workshop organized by EcoPro.

Dear Kasturiraju, thank you for the connect and providing me details on EcoPro. It was really useful and appreciate it.

Rgds,

-Ganapathi Bhat.

EM - EcoPro training summary.docx (15.3 KB)

Dear bhatji,

Thanks n appreciate your interest n committment, all the best. Please keep sharing the experiences of the same here to inspire all interested peoples.

Where is your attachment… ?

Also, can you provide the workshop person detail to get barricades, where you got done, please.

Thanks and regards.

Kasturiraju.

The attachment is with my earlier post. I can see it and download it… Please check again…

Cow cubicle loops or barricades : I am still working with the iron works fellow on finalizing the design. Once one set of cubicle loops are out, I will post all the details. I have also given him a stainless steel bowl to attach a pipe at the bottom, These will be the water bowls for the cows.

Hello,

We feed 50gm of Agrimin Forte mineral mix to all our cows. This mineral mix has 25.5% of Calcium in it. Which means, about 12.75 gms of Calcium is fed to the cows thru mineral mix.

Is there a need to give additional calcium supplement ? I assume the calcium fed thru mineral mix is sufficient.

Please share your thoughts.

thanks,

-Ganapathi Bhat

Dear bhat,

thanks for your reply and yes I have seen your attachement and thanks for your information sharing.

-

Have you started EM using in your dairy farm…?

-

About your quiery about calcium …you are true. Theoritically the calucalation what we does and feed through mineral mixture is sufficient based on that. But, actually… am of the opinion though we calculate and give where is the guarantee every thing gets absorbed or used in the system. We call it as bioavailability. That means these minerals can’t be converted 100% by animal i.e. absorbed and goes out of body either ways. apart from this the animal body demands varied quantity of calcium,phosphorous and magnesium at different stages of the pre and post calving.

Hence, to compensate/maintain these type of difficiencies we have to give supplements further 30gm per day/each for non-milking cow and 50 gm per day each of milking cow.

In market, you will get various such suppliments…we use one such VET MIN in our farm it cost around Rs. 175-00 to Rs. 200-00 per kg.

Thanks and regards,

kasturiraju.

Thanks Kasturiraju for the advise on Calcium supplement.

We have bought 1 litre EM (Cost is Rs. 335 including shipping). EM activation is in progress, it is a 7 day process. We will start using it after EM activation is complete. I will provide an update on the usage and benefits that we see.

Hello,

This is a query on Dairy cows conceiving.

I own a dairy farm with 17 cows. Cows come to heat at regular intervals. We do AI whenever they come to heat (after 16 hours of heat start). However the cows are not conceiving. for some of the cows , this is the third or fourth insemination.

Please advice on how to improve on this.

Some farmers have told me that - feeding cottonseed cake has negative effect on conceiving, is it true ?

thanks,

-Ganapathi Bhat

Dear bhat,

For dairy farmers there are lots of hurdles and challenges…in that one of the second biggest challenge is " Repeating " ![]() problem.

problem.

For this problem, there are several reasons and dairy farmer has to realy practice and adopt certain methods without fail to hold up the dairy farm…as a cow maternity home.

The reasons for it are :-

-

Genetics.

-

Nutritional deficit.

-

Vagina / uterus infection.

-

Improper/ imperfect A.I.

-

Failured semen i.e. cold chain failed.

-

Inferior quality semen.

-

Improper handling of cow while prior deliverying the calve.

-

Wrong time acess of Heat symptoms or attending it.

-

Stresses of any kind on the cow.

you have to analyse all these above reasons carefully and take successive actions on the same with local experienced Veterinarian…

However, I hope you will understand the kannada language and you can refer the attached file for further your reference.

all the best,

kasturiraju.